No products in the cart.

The Differences Between Laser Cutting, Plasma Cutting, and Waterjet Cutting Processes

The cutting technology is developing by the day thus providing the cutting industry with a wide range of cutting options. Some of the leading cutting technology that you can adopt include laser cutting, plasma cutting, and waterjet cutting. While the three cutting options are available in the market, they are worlds apart when it comes to the results they provide. Choosing the best has proven an uphill task for many. Here’s your golden opportunity of knowing the differences between the technologies.

1. Laser Cutting

The laser cutting technology involves the use of light that moves in a straight line towards your material and removing metal through vaporization. They are usually fast and excellent at cutting thin material. The technology uses laser gases and electricity.

2. Plasma Cutting

The plasma cutting technology cuts through electrically conductive materials using an accelerated jet of hot plasma. It removes metal by melting it and blowing it away from the work area. The plasma technology is excellent at cutting metal.

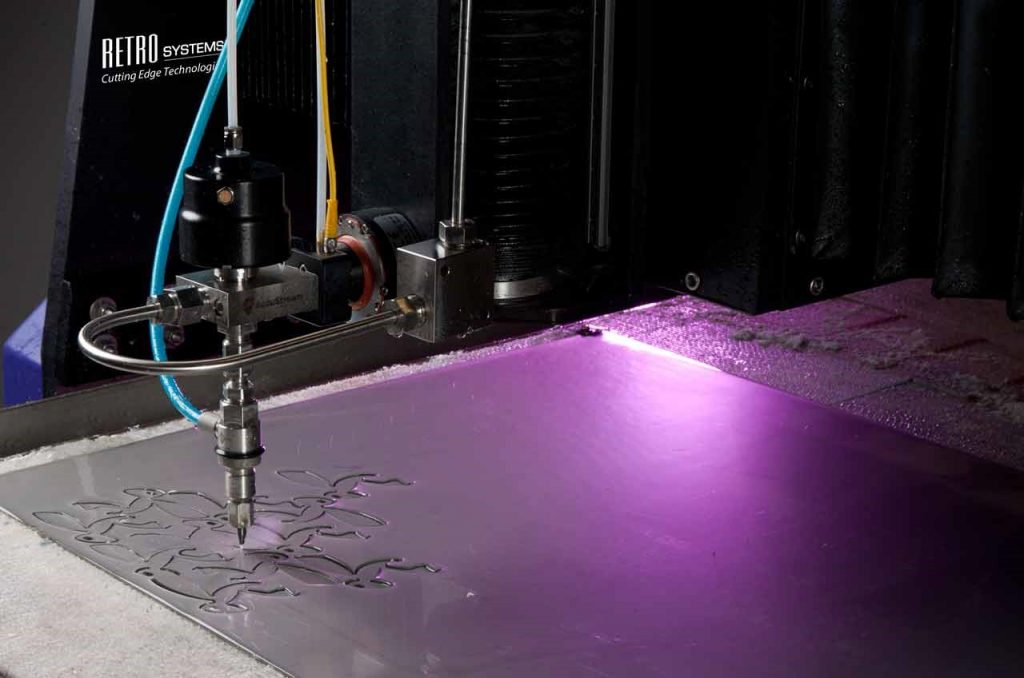

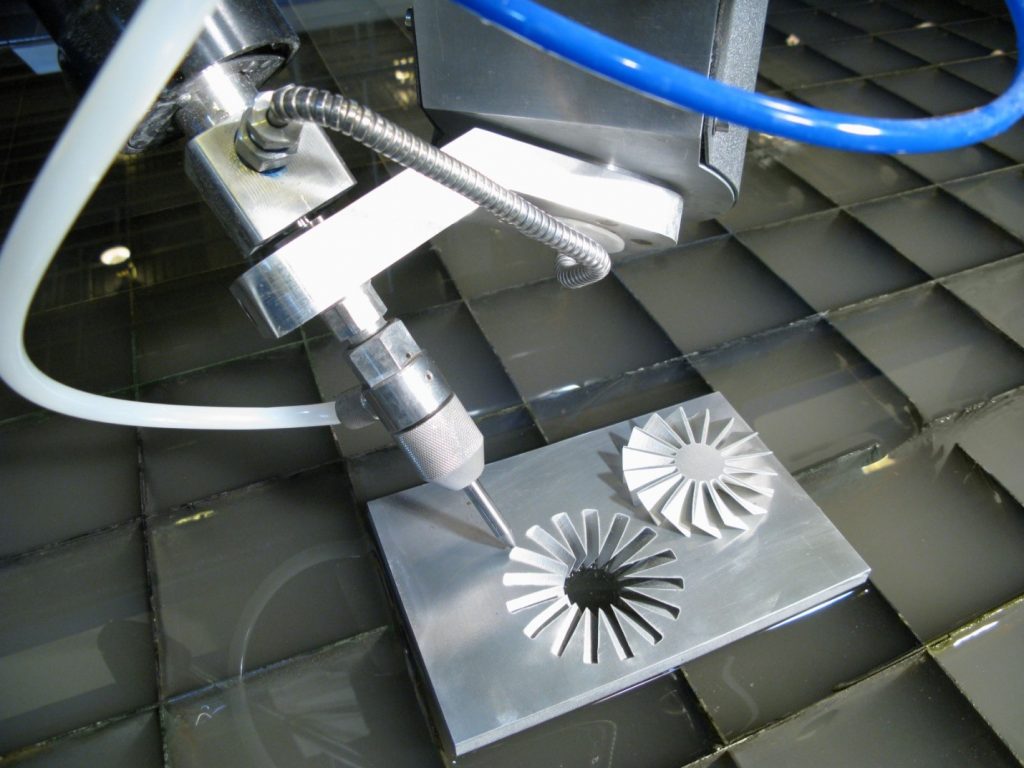

3. Waterjet Cutting

Waterjet cutting machine is the best among all other types of cutting media because it does not produce heat zones. Meaning that it supports the cutting of delicate materials that would either crack, bend, or melt. At the same time, there’s no distortion because of its cold cutting method. Waterjet is versatile and so allows the cutting of a wide range of materials ranging from the softest to the hardest. It achieves incredible precision with no hazardous waste.

Why is garnet used in most Waterjet Cutting process?

Abrasives form a vital component of the water cutting process. Waterjets without abrasives (pure waterjets) are excellent for cutting soft materials such as rubber and form. However, adding an abrasive substance increases the jets cutting capabilities. This way, you can cut steel, glass, and a whole range of other devices. Hence the abrasive that’s used will determine the type of machine outcome. A lot of materials have been tested for use in waterjet cutting. All experts agree that garnet is the best solution. A garnet abrasive provides superior cutting capabilities.

Here are the reasons why Garnet is used in most waterjet cutting processes:

1. Has the ability not only to alter the garnet feed rates but also adjust the amount of garnet the equipment consumes through the regulators’ dial gauge

2. Maximizes the flow of the garnet into the nozzles

3. Allows you to change the garnet flow settings depending on the type and thickness of the material you are cutting

4. Provides you with easy access to the regulator so that you can always switch to the type of garnet abrasive required

5. Achieves the smoothest cutting edge of your workpiece by providing accurate and consistent garnet flow

Conclusion

The cutting technology has improved both efficiency and quality in the cutting industry. The laser, plasma, and waterjet cutting are the best technologies available to the cutting industry. Waterjet cutting is arguably the best of the techniques. Adding an abrasive to the waterjet enhances its cutting capabilities. Garnet is mostly used in the waterjet cutting process.