The world would not be what it is today if it were not because of engineering. Hence, learning and pursuing a career in engineering is a top priority for a lot of people. When it comes to developing technical equipment for engineering education, Edibon stands out from the competition, as their technical teaching equipment is used worldwide today.

The history of Edibon

The company was founded in Madrid, Spain, in 1978, as a family business dedicated to distribution to other manufacturers. It was not until 1981 that they exported for the first time, to Mexico. Only a few years later, in 1984, they designed their first unit with SCADA, and 10 years later they developed their first EDIBON SCADA-NET (ESN). An important milestone was achieved in 2005, when the company opened its first branch in Atlanta, in the United States. In 2007, they designed their first industrial teaching unit, a product that would direct their strategy for the years to come. After opening a branch in India in 2013, they then started building a new factory in the Technology and Science Park of Mostoles, Madrid. Edibon currently manufactures and exports their products to over 150 countries in the world. In fact, around 98% of the company’s production is exported to institutions in more than 140 countries, including both Higher and Technical education centres, as well as Vocational Training or Business Training centres worldwide.

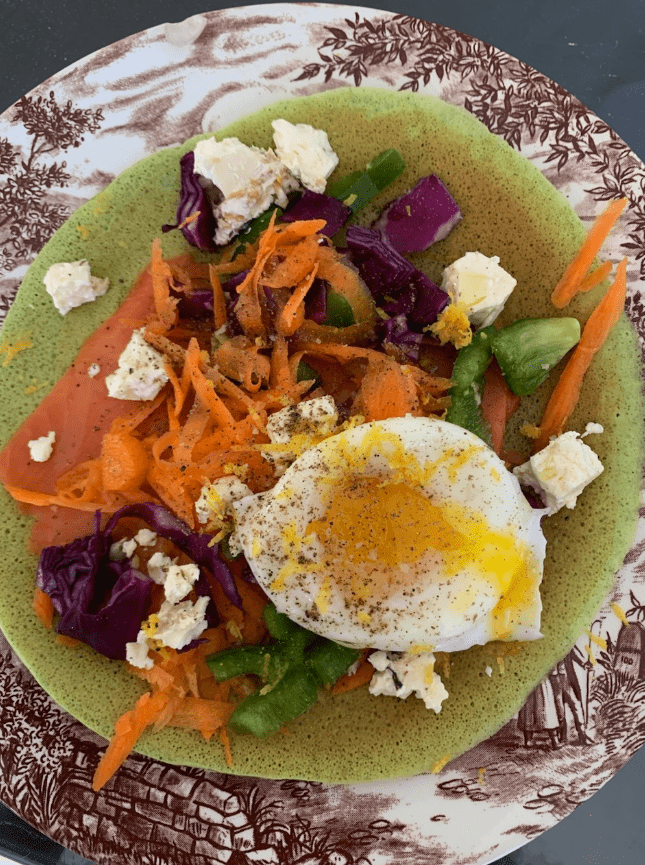

The use of pilot plants

Edibon develops pilot plants in order to assess and analyse a set of unit operations, so that they can be then developed at a real and larger scale. A pilot plant is then a smaller scale process plant which is designed to be able to obtain information that can then be used to scale it up in much bigger processes. In these plants we can carry out feasibility studies of designs and processes, thus reducing the cost of the initial investment. In present times, we could also use simulators to study these processes, however they do not allow for predicting behaviour or for obtaining data from new processes before they are optimised. That is why pilot plants are much more beneficial, for this purpose. Some of the pilot plants designed and which can be viewed on Edibon’s website are about chemical engineering or Food & Water technologies.

Unit operations in the chemical industry

We can define unit operations as the physical changes that take place in the processes within the chemical industry. They arise when studying different chemical processes in which a different operation is apparently performed, however they have the same basis. We can classify these operations within three types:

- Mass transfer: In this case, there is a change in the composition of the matter, perhaps including a chemical change. This includes distillation, absorption, adsorption, extraction and ion exchange, and the change is mainly physical.

- Energy transfer: This consists of energy change that could result in a change of state due to a change of pressure and/or temperature. This transfer includes the evaporation, drying, lyophilisation, sublimation, crystallisation and humidification.

- Momentum transfer: In this type of operation, there is a change in kinetic conditions of the matter and it includes filtration, sedimentation, flotation and centrifugation.

By using their know-how (known as SCADA in Edibon’s environment or Supervisory Control and Data Acquisition), the company has been able to become a leader in technical equipment for engineering education, achieving a global presence and becoming a key part in teaching and research when it comes to engineering.