While the construction industry is continuously evolving and society is becoming increasingly environmentally conscious, sustainable construction practices are now more critical than ever before. The principles for microtunneling are no new concept, but the environmental benefits are only being noticed more recently.

But what is microtunneling, and how can it benefit our planet?

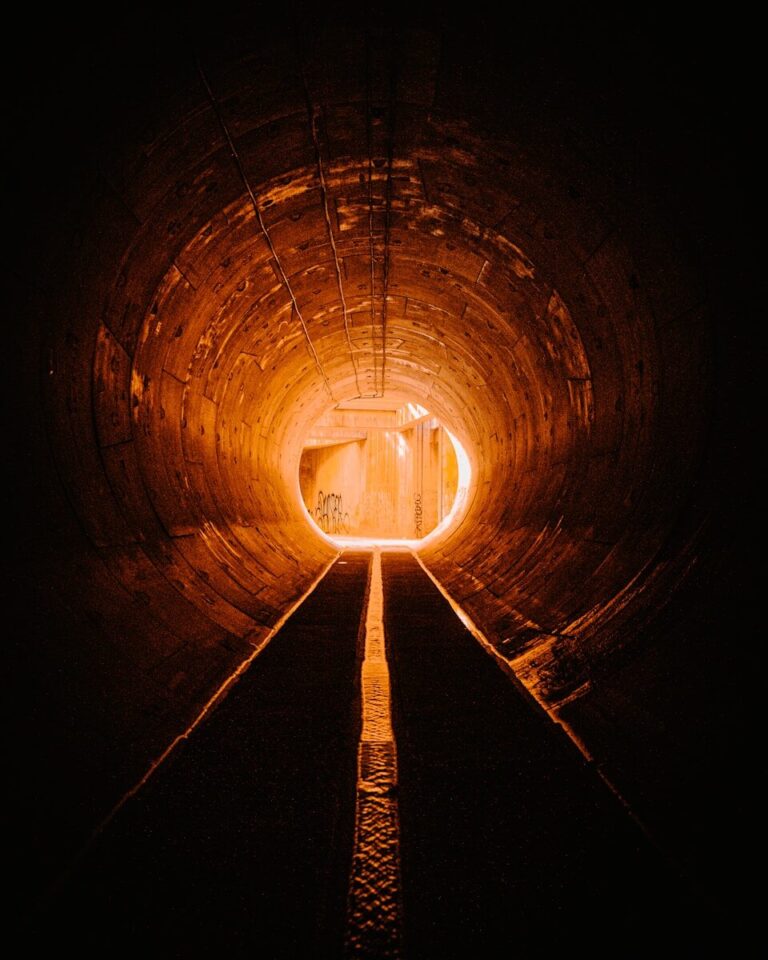

Microtunneling is a construction practice that involves digging techniques that merge pipe-jacking methods with a remotely controlled and guided approach to construction. Due to the extensive techniques used, microtunneling processes eliminate the need to dig massive trenches to lay pipes, ensuring less destruction to the environment and the community.

The Japanese first developed this pipe-laying method in the 70s, yet it remains one of the most accurate approaches to pipeline installation to this day.

With that said, let’s look at the primary advantages microtunneling offers our environment.

Cleaner Processes

Microtunneling involves incredibly clean processes. The technique ensures quantities of incoming and outgoing construction materials are significantly reduced when compared to open-cut construction techniques. The reduction in materials is much less harsh to the surrounding area while also boosting safety for construction teams.

The amount of soil and material spillage is minimized, and no liquid surface is present when injecting fluids at high pressure, which is usually present in horizontal direction drilling techniques. As a result, there is far less disturbance to the immediate environment.

A Safer Work Environment

When compared to most other pipe-laying methods, microtunneling offers the safest work environment for construction teams; it is the safest underground construction technique. While open-cut construction usually requires that teams follow existing utilities, roadways, and other obstructed surfaces, microtunneling avoids environmental destruction by interfering with surface obstructions less.

In construction processes, it’s crucial to minimize disturbance to natural barriers and waterways beneath ground level while still getting the job done. For this to be possible, construction companies often need to use trenchless methods to avoid potentially devastating consequences to employees and the environment. Microtunneling is the most practical solution to date.

Vacuum Extraction Techniques

Unlike most other underground construction practices, microtunneling focuses on vacuum extraction systems to support a cleaner environment. This approach offers ongoing support to the surface using pipe jacking techniques. Vacuum extraction systems can minimize worksite carbon footprint substantially.

The types of techniques used in microtunneling are far more efficient and environmentally beneficial than those used in open-cut construction. Construction companies will also benefit from a reduction in employee injuries while lowering the risk of injury to the general public and the surrounding environment. At the same time, project costs are reduced for several other blatant reasons.

Trenchless construction methods include microtunneling, tunneling, horizontal directional drilling, pipe ramming, and horizontal auger boring. Of these methods, microtunneling is the safest and most efficient. However, construction projects often incorporate several trenchless techniques to meet goals and boost efficiency.

On the other hand, open-cut construction methods are gradually being phased out of the industry due to the harmful impacts on the general public, construction employees, and the environment.