Glass is a fragile material likely to break at the slightest shock. Glass objects are easily replaceable, but they are also repairable. When the damage is minimal and confined to a small area (a few centimetres), it is quite possible to save a glass object.

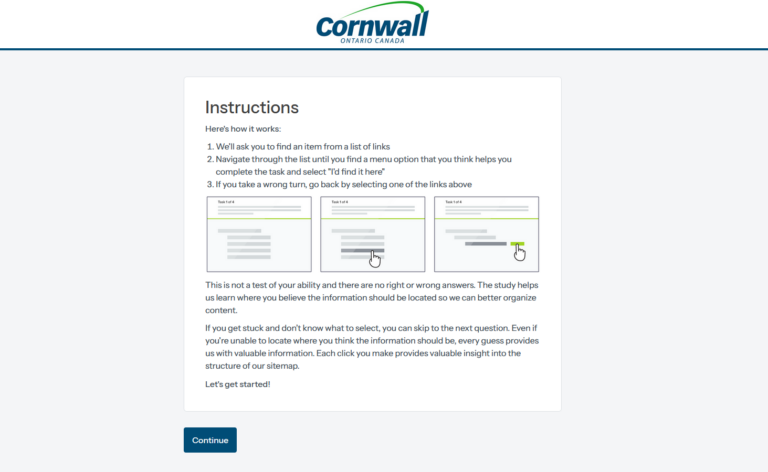

The glass repair and restoration work’s main task is to mechanically restore the damaged area using a polymer (adhesive resin) and then polymerize the patched area to stabilize the structure of the material and improve the appearance of the repaired area. The polymer is applied using a special injector fixed to the mounting bridge. Before applying the polymer from a crack or chip, it is necessary to thoroughly remove air and ensure no air inclusions in the filled area. Suppose the air is not entirely removed from the damage. In that case, it will significantly reduce the adhesive characteristics of the polymer when repairing and processing this area and will have a negative effect on the overall appearance of the fixed surface.

The intervention takes place on-site and without removing the glass. Technicians inject a resin into the impact. Secondly, the resin will be polymerized under ultraviolet radiation. The resin hardens and consolidates the glass. Our intervention makes it possible to solidify the glass while reducing the unsightly aspect of the impact. The resin treatment used by technicians can be very effective for the reconstruction of part of the glass. So, on glass guardrails with broken angles, technicians can reconstruct the glass’s missing piece, giving the glass its initial appearance. If the repair work is carried out, the improvement in the glass defect formation is at least 70 – 95% (depending on the size and complexity of the damage).

Note: none of the systems for the repair and restoration of glass defects on the modern market can guarantee 100% visual restoration of the damaged surface. An outstanding repair kit provides the highest quality restoration work and a more efficient result than any other standard repair system. The system is developed based on the latest technologies and, if used correctly, guarantees visual defect recovery by 80 – 95%.

Thus, if one expects to improve the damaged surface’s appearance by more than 80 – 95%, they should seriously consider replacing the damaged glass completely. All repair and restoration work represent a particular compromise. Still, most clients are satisfied with the quality of restoration work since they provide a significant improvement in the appearance of the damaged surface and reliable protection against destabilization and destruction of the glass structure.

Remember that the main reason for restoring damaged glass is to ensure its strength and extend its lifespan. The visual improvement in appearance should be regarded more as an additional benefit of the renovation system.

Depending on the structure and purpose, all standard glass can be divided into two main types – tempered glass (reinforced structure) and laminated glass.

Tempered glass is made up of a single structural layer that has been processed during production to break completely when subjected to a strong impact, significantly reducing the risk to users in an accident. Due to special processing, damage to even the smallest part of the tempered glass leads to a decrease in the structure’s stability and the disintegration of the structure into many tiny fragments. These technical characteristics of tempered glass exclude any possibility of restoration in case of damage.

Unlike tempered glass, minor defects in laminated glass can be repaired, with a significant improvement in the damaged surface’s appearance. Laminated glass consists of two glass panels connected with an impressive technical layer made of PVB (polyvinyl butyral) plastic. Thus, laminated glass can be roughly divided into inner, outer, and intermediate layers.

The main types of glass damages

The sooner the repairing of chips and cracks in the glass begins, the less costly the procedure will be. Technical experts carry out glass restoration according to a pre-formed effective technology, using high-quality consumables and modern equipment. First of all, the specialists determine the type of defect. There are several main types of damage.

- “Paste” – is formed as a result of the hard impact of worn-out wiper blades, can be removed by polishing.

- Scratch – slight damage to the outer layer of the glass. It can be removed by polishing.

- Shcherbina – minor damage up to 1 mm deep without penetrating the outer layer. Auto glass repair is not required in this case.

- Chipping is a severe defect, as a result of which the outer layer of glass breaks through. It can have various shapes (vortex, “bull’s eye,” “star,” etc.), it requires urgent repair of windows.

- Crack – damage, as a result of which the glass layer splits into two parts. Often formed from small chips and requires repair. Large cracks lead to the need to replace the windshield.

Features of glass repair

The formation of defects in the glass is mainly caused by mechanical damage resulting from the ingress of stones or hard objects coming directly to the glass and exert high pressure. Many people are in no hurry to remove cracks, scratches, and chips on the glass, especially if they are located closer to the edge and do not interfere with the view. However, any damage tends to expand gradually. Over time, any minor scratch can render the glass unusable and will have to be replaced. Therefore, it is recommended to repair chips and cracks on the glass as soon as possible.

For instance, it is advisable to repair the glass of a car immediately after receiving mechanical damage. This will save a lot of time and financial resources. When the glass has been repaired, it is advisable to take these steps below.

- Cover the damage with a small paper strip.

- Seal with tape to ensure protection from contamination.

- Do not put direct heat on the glass.

- Do not subject the repaired glass to vibrations.