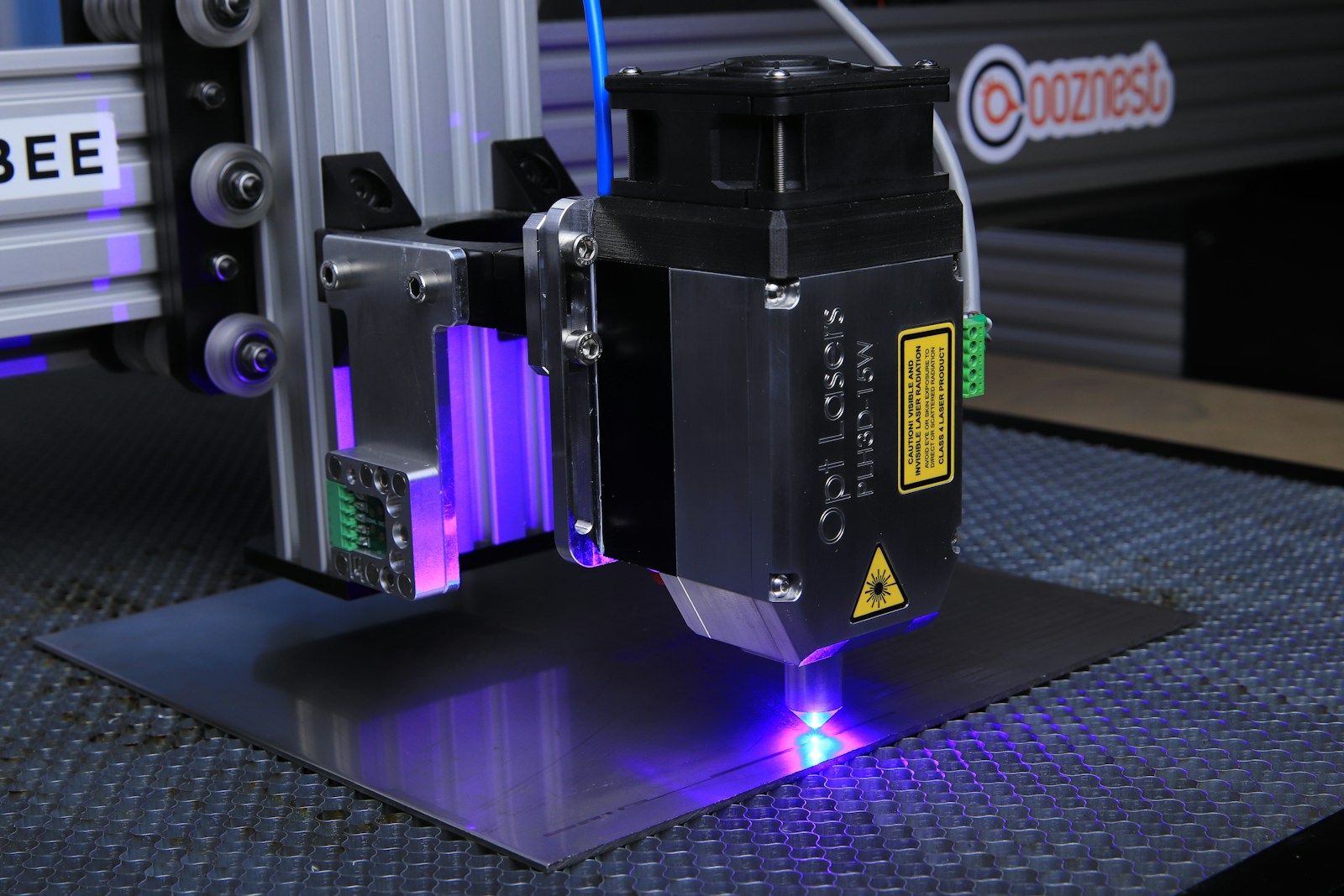

In the ever-evolving world of craftsmanship and manufacturing, laser engravers and cutters have become indispensable tools. Whether you’re a hobbyist creating intricate designs or a professional working on large-scale projects, these devices offer unparalleled precision and versatility. From customizing delicate jewelry to cutting robust industrial materials, the applications are virtually limitless.

Choosing the right laser engraver or cutter is crucial for achieving both efficiency and high-quality results. The proper tool not only enhances productivity but also ensures that your final product meets exact specifications. As technology advances, the market offers a variety of options tailored to different needs, making it essential to understand what each tool can offer.

The Ultimate Guide to Laser Engraving and Cutting

Understanding Laser Engraving and Cutting

What is Laser Engraving?

Laser engraving is a process that uses laser technology to etch designs, text, or images onto various surfaces. This technique entails directing a concentrated beam of light onto the material’s surface, effectively vaporizing it and leaving a permanent mark. Unlike traditional engraving methods, laser engraving does not involve physical contact with the material, which minimizes wear and tear on the tool.

Common Applications and Materials Used

Laser engraving finds applications like laser cutter Canada in diverse fields due to its precision and versatility. Common applications include personalized gifts, industrial part marking, jewelry making, and signage. The materials that can be engraved with lasers are equally diverse:

- Wood: Ideal for decorative pieces, furniture accents, and custom signage.

- Acrylic: Perfect for creating clear or colored engravings used in awards and displays.

- Metal: Frequently used for producing detailed markings on tools, plaques, and identification tags.

- Glass: Utilized in creating intricate patterns on glassware or windows.

What is Laser Cutting?

Laser cutting employs similar principles as laser engraving but focuses on cutting through materials rather than just marking their surfaces. This method involves directing a high-powered laser beam onto the material to slice through it with extreme precision.

Differences Between Laser Cutting and Traditional Cutting Methods

Traditional cutting methods like sawing or milling involve physical contact between the cutting tool and the material being cut. This can lead to tool wear over time and may not produce as clean edges as laser cutting can achieve.

In contrast:

- Precision: Laser cutters can achieve far more intricate designs without causing stress damage to materials.

- Speed: They work faster as they don’t need frequent tool changes or maintenance.

- Versatility: Capable of cutting through a wide range of materials including textiles, plastics, metals, wood-based products like MDF (Medium Density Fiberboard), among others.

Key Features to Consider When Choosing a Laser Engraver/Cutter

Power and Speed

The power wattage of a laser engraver/cutter significantly impacts its performance:

- Higher Wattage: More powerful lasers like OMTech Canada (e.g., 60W – 150W) can cut thicker materials effortlessly while maintaining speed efficiency.

- Lower Wattage: Less powerful lasers (e.g., under 50W) might be sufficient for engraving but often struggle with thicker cuts.

Speed also plays an essential role in project completion:

- Faster Machines: These machines ensure quicker turnarounds which might be vital in commercial settings where production rate matters.

Material Compatibility

When choosing a laser machine consider what types of materials you plan on working with most frequently:

List of Common Materials

- Wood

- Acrylic

- Metal

- Leather

- Glass

Material compatibility affects your choice significantly because different materials require specific power levels for efficient processing without causing damage or incomplete cuts/engraves.

Precision & Accuracy

The precision offered by your chosen machine dictates how detailed your work will be:

The Role of Precision in Detailed Work

Fine detail work such as intricate patterns on jewelry requires highly precise machines capable of achieving minute detailing without errors.

How Accuracy Impacts Overall Project Quality

Accurate cuts ensure all parts fit together perfectly when assembling projects from multiple pieces – crucial for models/prototypes where even slight deviations could render parts unusable.

Software Compatibility

Modern laser engravers/cutters rely heavily upon software interfaces both for designing new creations & controlling machine operations:

Overview Of Popular Software Used With Laser Engravers/Cutters

Software such as CorelDRAW®, Adobe Illustrator®, AutoCAD® remains popular among professionals due largely because they offer extensive design capabilities coupled seamlessly integrated workflows into these hardware solutions,

Ease-of-use within said interface cannot be overstated since overly complicated systems often result slower adoption rates ultimately harming productivity overall!

Conclusion

Investing into right ‘Laser Engraver/Cutter’ demands thorough understanding regarding key aspects discussed above — whether importance lies within ensuring correct wattage/speed parameters met given job requirements; evaluating material compatibilities beforehand prevent future headaches down line; recognizing absolute necessity having both precision accuracy order maintain top-tier quality standards consistently across board regardless nature individual projects undertaken!