There are many different types of commercial pumps available on the market, each with its advantages and disadvantages. Choosing the right pump for your particular application is vital to getting the most efficient and effective results. This article will explain the different types of commercial pumps and how to select the best one for your needs.

Types of Commercial Pumps

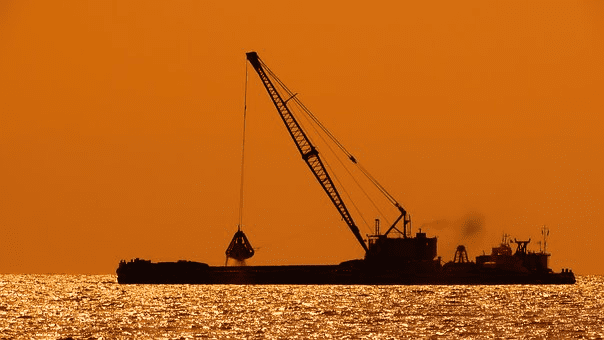

There are different types of commercial pumps. Each has its purpose and is designed differently to accommodate various applications. If your pond needs dredging, you will need a commercial pump with a high flow rate. If you need to move water from one location to another, such as irrigation, you will need a pump with a lower flow rate. The three main types of commercial pumps are:

Positive Displacement Pumps

A positive displacement pump is a type of pump that moves fluid by displacing it with a mechanical piston, rotor, or other devices. This type of pump is often used in applications with high accuracy and repeatability, such as in metering applications. Positive displacement pumps are also typically used for viscous fluids or fluids with particulates, as they can handle these substances without damage.

Submersible Pumps

A submersible pump is a type of pump that is designed to be submerged in water. This type of pump is often used in applications where space is limited, such as wells or tanks. Submersible pumps are also typically used for fluids with high solids, as they can handle these substances without damage.

Centrifugal Pumps

Centrifugal pumps are the most common type of commercial pump. They use a rotating impeller to generate centrifugal force, which creates pressure to move fluids through the pump. Centrifugal pumps are suitable for many applications, including water supply and irrigation, but they are not suitable for pumping highly viscous liquids.

Selecting the Right Commercial Pump

When selecting a commercial pump, it is vital to consider the following factors:

Flow Rate

Flow rate is the fluid the pump can move per minute. Choosing a pump with a flow rate that is appropriate for your application is crucial. If the pump has a too low flow rate, it will not be able to meet your needs, and if the pump has a too high flow rate, it may be more than you need and could be inefficient.

NPSH

The net positive suction head (NPSH) is the amount of pressure required to prevent cavitation in the pump. Cavitation is a condition where bubbles form in the liquid due to the low pressure, which can damage the pump. Choosing a pump with a high NPSH is crucial if you are pumping fluids that are likely to vaporize, such as water.

Viscosity

Viscosity is a measure of how thick or thin a liquid is. Choosing a pump suitable for the viscosity of the liquid you are pumping is essential. If the viscosity is too high, the pump may not be able to move the liquid, and if the viscosity is too low, the pump may not generate enough pressure to move the liquid.

Pressure

The pressure is the amount of force that the pump can generate. Choosing a pump with enough pressure to meet your needs is vital. If the pump is not powerful enough, it will not be able to move the fluid through your system. If the pump is too powerful, it may damage your system or cause problems with your process.

Temperature

Temperature is the measure of how hot or cold a liquid is. Choosing a pump suitable for the temperature of the liquid you are pumping is crucial. If the temperature is too high, the pump may not be able to move the liquid, and if the temperature is too low, the pump may not generate enough pressure to move the liquid.

Corrosion Resistance

Corrosion resistance is the ability of a material to resist corrosion. It is essential to choose a pump made from materials resistant to the chemicals in your application. If the pump is not corrosion resistant, it may be damaged by the chemicals and will not last as long as a corrosion-resistant pump.

Efficiency

Efficiency is a measure of how well the pump uses energy. It is crucial to choose a pump that is efficient if you want to reduce your operating costs. An efficient pump will use less energy than an inefficient pump, costing less to operate.

There are many different types of commercial pumps available on the market. Choosing the right pump for your particular application is vital to getting the most efficient and effective results. This article has explained the different types of commercial pumps and how to select the best one for your needs.