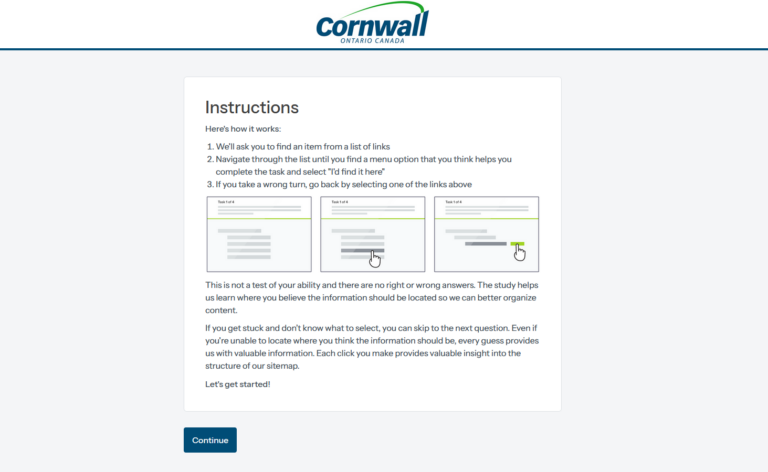

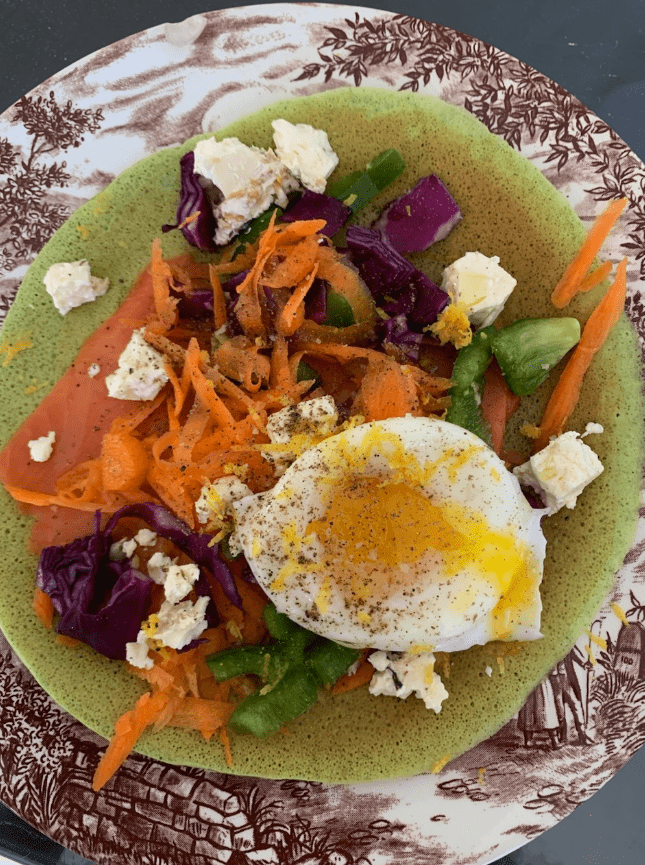

If you like salads as much as I do, you look for the best lettuce and greens. Among its many offerings, Cornerstone Organics grows and distributes great salad greens. They are fresh and flavourful and during the cooler months, grown in an Aquaponic system.

I recently visited Cornerstone’s 200-acre farm with a friend and got a fantastic tour of the aquaponics setup from the owners Matt Lalonde and Jamie McRae.

Aquaponics is a sustainable food production method that combines fish farming “aquaculture” with soilless plant cultivation “hydroponics”. Fish poop provides nutrients for plants, while plants filter the water for the fish, creating an almost closed-loop system that requires minimal external inputs. It does however require quite a bit of expertise and attention to detail. Using up to 90% less water than regular agriculture, aquaponics provides a resource-efficient, eco-friendly way to grow high-yield, high-quality produce year-round.

As of 2021, Cornerstone was the 1st certified organic Aquaponic farm grower in Ontario and is currently the only one in Canada for vegetables.

How It’s Done:

Fish tanks

It starts with the fish who live in one or more large plastic fish tanks.

Matt’s main tank houses some 300 tilapia – a popular choice due to their fast growth rates and hardiness. His fish are born on the farm to prevent disease in the breeding tank and are fed organically approved high-quality trout & salmon feed.

Filtration

The heart of the system is the filtration system. It’s important to maintain clean but balanced water for the fish (too clean and the fish die). A bio-filtration unit uses beneficial (nitrifying) bacteria to break down solid waste and excess nutrients in the water. These bacteria hang out in the filtration tank beads and turn fish waste into nitrates that feed the plants.

The fish food contains calcium, magnesium, potassium and proteins. Fish are fed one to two times a day depending on their needs (age and size are factors). The fish will use what they need and excrete the rest. Their poop retains much of these elements and bacteria break down solids into usable fertilizer for plants that is rich in micro-nutrients. Part of the filtered water is sent back into the fish tank to help maintain water levels while another portion is sent to the greenhouse to feed their lettuce, later returned to the fish tanks. Some fish water is also bottled and sold as ready-to-use liquid fertilizer for your house plants.

The system (more complex than I can illustrate in this article) has various tanks to collect, “filter” and distribute nutrient-rich water to the grow beds. Other tanks are used to breed baby tilapia.

Male tilapia are geared to mate. A male with only 1 female will harass her until she dies so they have a ratio of 1 male to 6 females and places for females to rest (who knew).

Matt’s family are not big fish eaters so they don’t consume much tilapia. After talking to him I feel like he likes his fish to the point of that they have become aquatic pets. Still, he could (and might) sell them for food. People are worried about factory farmed tilapia, but these are “clean” fish. Down the line he’s also thinking about stocking koi. They do the same job as tilapia and they are good sellers to pond owners.

Pumps and plumbing

Fish cannot be in direct contact with the plants as they will eat the roots. So, pumps circulate the water from the fish tanks to the greenhouse grow beds and return the plant-cleaned water to the fish tank(s). A LOT of pipes and hoses connect the different components and Matt’s plumbing background enables him to understand and maintain the system.

Grow beds and greenhouse

To access the lettuce, we follow sanitation procedures to prevent introducing bugs and pathogens into the greenhouse. We change into plastic footwear, step through disinfectant, wash our hands and vacuum sleeves and pant legs. Despite this precaution, they still lose plants. “It’s an ongoing battle” says Matt.

While the fish portion of the tour is fascinating because of the intricate setup, the greenhouse is my favourite area with long beds growing luscious lettuce and other greens.

Matt’s grow beds use a method called “deep water culture” (DWC). In DWC, plants are grown on floating Styrofoam rafts that sit on the surface of the water in the grow beds (which are about 8” deep). These rafts have holes where plants are inserted, allowing their roots to grow down absorbing nutrients directly from the water. This direct access to nutrients allows plants to grow rapidly and produce high and very nutritious organic yields. The rafts support the plants, keeping them upright as they grow, preventing damage, and facilitating easy harvesting.

Various plants can be grown in aquaponics, including herbs, vegetables, and fruits. The choice of plants depends on the system’s size, available space, and climate. Lettuce bolts when exposed to 80 F for more than 3 days so it’s grown with aquaponics in cooler months. This summer they will grow cucumbers and tomatoes in the greenhouse as these are more heat-tolerant.

Plant care

Despite the cleaning we do before entering, they get aphids and the first section near the entrance is composed of “sacrificial plants” that attract and contain the aphids to a small area. The plants can be cleaned with organically approved insecticidal soap. 9000+ ladybugs and a host of tiny parasitic wasps help to control the aphids naturally.

While the system is mostly closed-loop, Matt must pay close attention to his fish and work with the natural cycles of fish and plants. At times he can add minimal inputs. For example, when fish are “teenagers” they need more calcium to grow and the overall system can use additional calcium.

Nothing goes to waste on a well-run organic farm. Slightly overgrown but tender lettuce is bagged while very overgrown produce is fed to their goats.

Plant starting

To enjoy a plentiful harvest, seeds must be planted.

At the end of our tour, Matt brought us to the seeding bench where he plants his seeds. It’s a long table with supplies off to one side of the entrance. Behind him are covered shelves with lighting where seeds germinate and grow big enough to be moved to the main growing areas.

Armed with music or videos to keep him company, this is a meticulous but relaxing job of inserting seeds into very small “jiffy” type pellets that germinate the seeds to the point where they can be transplanted in the growing rafts.

To maintain his organic certification Matt must account for all the seeds he buys, all the seeds he plants and all the plants that are produced. This gives certification bodies a way of tracking what organic seed stock he is using and how many plants are produced.

QR codes keep track of the work done and plants seeded, planted or harvested on every given day. All of this info goes into a database.

Conclusion:

What I like about this concept is that it allows the farmer to grow an abundance of very nutritious vegetables (and fruits) year-round while also raising healthy, edible fish. The thinking is that plants grown this way are nutritionally similar to veggies grown in fertile soil gardens using natural compost – both of which are nutritionally superior to factory-farmed produce – and neither rely on harmful pesticides or herbicides.

Cornerstone will have organized tours in the fall and I highly recommend you go to see how they do it all.

I ended my tour with a comment “The teaching spirit is strong in you” to Matt. The planned 10-15 minute visit lasted well over an hour learning the ins and outs of aquaponics.

Feature photo: NastyaSensei

Article photos: Louise Mignault, Phyllis Sarault

Please note: Cornerstone has a variety of events that are advertised on their website and FB page. This includes plant sales (Friday May 17 and Saturday May 18), a CSA program, home baked goods etc.