Key Takeaways

- Vacuum pumps are vital to modern industry, enabling processes that require controlled environments.

- There are different types of vacuum pumps, each with unique designs and capabilities tailored to specific applications and performance requirements.

- Choosing the right pump involves evaluating vacuum level, speed, durability, compatibility, noise, and energy use.

- Partnering with a trusted supplier ensures proper selection, installation, and long-term reliability.

Have you ever wondered how your coffee stays fresh for months? Or how your smartphone’s tiny circuits are made? The answer may be simpler than you think: vacuum pumps.

These machines suck out air to create empty space, which factories, laboratories, and hospitals can’t work without. They’re the reason food lasts longer, surgeries are safer, and rockets don’t explode in space. Yet most people have no idea they exist.

So, how do they work? Here’s a detailed guide on what vacuum pumps are and how they power the modern industry:

What Is a Vacuum Pump?

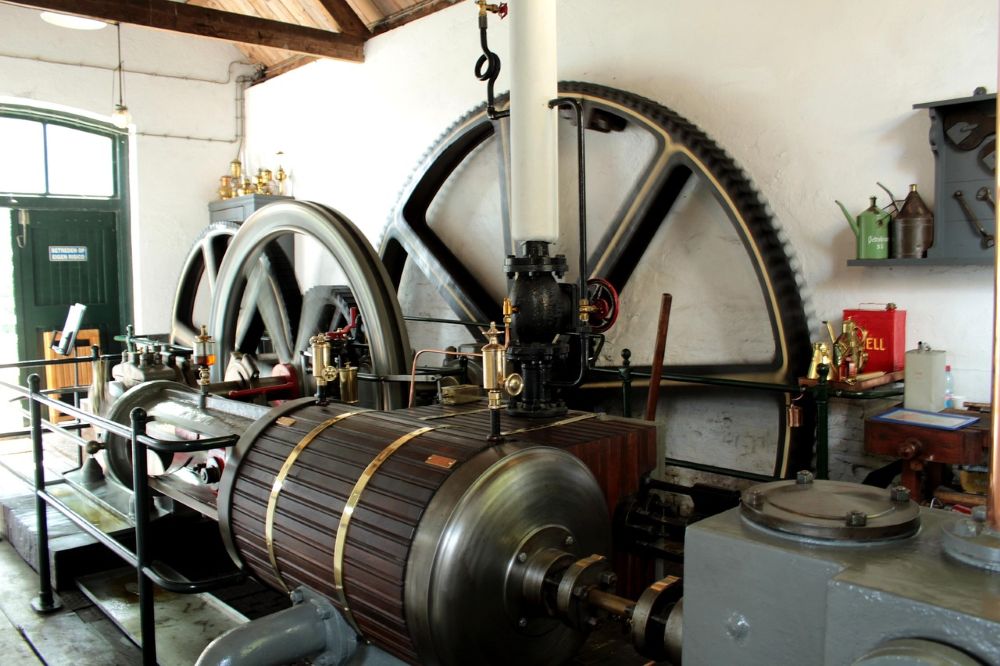

A vacuum pump removes gas molecules from an enclosed space, leaving behind a vacuum. This controlled environment is essential for manufacturing processes where contamination, oxidation, or unwanted chemical reactions can ruin the final product. The concept has existed for centuries, but today’s pumps are engineered for precision and reliability.

In an industrial vacuum system, pumps often work with components like vacuum valves and fluids to maintain optimal performance. The pump is just one part of a broader setup that may include pressure sensors, filters, and pump control systems. Together, these elements help achieve specific pressure ranges suited to each application.

The efficiency of a pump depends on factors such as the design, size, and intended use. A pump for vacuum filtration in a laboratory won’t have the same configuration as one designed for large-scale material handling in a factory. This adaptability makes vacuum pumps a cornerstone of many sectors.

To choose the best vacuum pump, look for reputable suppliers, such as Northwest Flow Technologies, with a proven track record in delivering high-quality equipment and comprehensive support. A trusted supplier should provide reliable pumps and offer engineering expertise, installation services, and ongoing maintenance to keep systems running at peak efficiency.

Types of Vacuum Pumps

Vacuum pumps are grouped according to how they create and sustain a vacuum. While there are many subcategories, there are three main categories:

Positive Displacement Pumps

Positive displacement pumps work by trapping air in a chamber and then expelling it to create a vacuum. This design is versatile, reliable, and found in various applications. Some commonly used positive displacement pumps include:

-

- Rotary vane vacuum pumps: Rotary pumps use vanes mounted on a rotor to form a seal and move gas out of the chamber. They’re often belt-driven for smooth operation and are mostly used in refrigeration servicing and laboratory work.

- Diaphragm vacuum pumps: These pumps feature a flexible membrane that pushes gas out without oil or fluid contamination, making them ideal for clean processes in medical, laboratory, and chemical applications.

- Dry piston pumps: These pumps are built for durability and minimal maintenance. They’re well-suited for portable systems and small-scale industrial tasks.

- Dry vane pumps: These pumps offer oil-free performance, making them ideal for food packaging lines and light-duty vacuum conveying. Avoiding oil contamination is critical in food and pharmaceutical production, and these pumps help maintain that standard.

Selecting the right positive displacement pump helps industries match performance needs with operational requirements. This choice ensures efficiency and reliability in their vacuum systems.

Momentum Transfer Pumps

Momentum transfer pumps accelerate gas molecules in one direction, pushing them toward the exhaust instead of trapping them. This category includes several key designs:

-

- Turbomolecular vacuum pumps: Turbomolecular pumps use high-speed rotors to collide with gas molecules, moving them out of the chamber. They are essential for achieving ultra-high vacuum levels in applications like semiconductor manufacturing and scientific research.

- Diffusion pumps: These pumps rely on vapor jets to propel gas molecules toward the exhaust. They have fewer moving parts in the pumping chamber but require precise fluid management for efficient operation.

- Screw vacuum pumps: Screw pumps feature screw-shaped rotors that move gas along the housing in a continuous motion. They provide a steady flow with minimal vibration, which is valuable in sensitive production environments.

Momentum pumps offer the precision and stability needed for industries where even minor fluctuations can disrupt results. Choosing the right pump ensures optimal vacuum conditions for demanding, high-performance applications.

Hybrid Vacuum Systems

Hybrid vacuum systems combine elements of positive displacement and momentum transfer designs. They use one pump type to achieve an initial rough vacuum and switch to a different pump to reach much lower pressures.

For example, a rotary vane pump might remove most of the air, and then a turbomolecular pump takes over to achieve ultra-clean, low-pressure applications. This approach is often used in aerospace testing facilities, advanced coating operations, and high-end manufacturing, where speed and precision are essential.

How Vacuum Pumps Power Modern Industry

Vacuum pumps are indispensable in many industrial sectors. Each industry uses them differently, but the goal is always to create a controlled environment that allows specialized processes to take place.

Here are a few areas where vacuum pumps are most critical:

Semiconductor Manufacturing

During semiconductor fabrication, even the slightest impurity can destroy an entire microchip. Cleanrooms rely on advanced vacuum systems to eliminate airborne particles and stabilize the environment.

Turbomolecular vacuum pumps maintain the extremely low pressures for physical and chemical vapor deposition processes. These precise conditions ensure each layer of material is applied accurately and without defects.

Vacuum valves carefully manage the flow of gases, allowing sensitivVacuum pumps help in preserving the freshness and quality of food products. They’re a key part of health-conscious packaging systems, which depend on them to remove oxygen from bags and containers before sealing.

This process helps slow spoilage and keeps food safe for longer periods. Rotary vane vacuum pumps are a popular choice in this sector. They deliver reliable performance even in high-volume production lines where consistency is critical.

In processing facilities, water vacuum pumps support cooling systems and liquid removal processes that help maintain operational efficiency. Dry vane pumps excel in vacuum conveying powdered ingredients. They ensure clean and efficient transfers without the risk of contamination.

Beverage manufacturers also rely on vacuum filtration pumps to clarify liquids such as juice or wine. This method preserves flavor because it avoids using heat during the process.

The removal of air eliminates the environment bacteria need to grow. As a result, these systems can extend shelf life and keep products tasting fresh. They also help maintain consistent quality from the production floor to the consumer’s table.

Food and Beverage Industry

Medical and Pharmaceutical

Vacuum technology is crucial in healthcare and pharmaceutical operations. In hospitals, pumps drive surgical suction devices that clear airways or remove fluids during procedures, helping maintain a clear surgical field. Diaphragm vacuum pumps are a common choice for these tasks because they deliver clean, oil-free air that meets strict medical standards.

Pharmaceutical manufacturing also depends on vacuum systems to maintain sterile conditions throughout production. They’re essential for processes such as freeze-drying vaccines and removing solvents from chemical formulations. Careful fluid management in these systems prevents cross-contamination, making the selection of compatible vacuum fluids and seals a critical step in equipment setup.

Advanced diagnostic tools further highlight the importance of this technology. Instruments like mass spectrometers use turbomolecular vacuum pumps to achieve the ultra-low pressures needed for analyzing samples at the molecular level. This precision ensures accurate results in both research and clinical testing.

Aerospace and Research

Engineers in aerospace testing must recreate the extreme conditions of outer space to validate equipment performance. Large vacuum chambers make this possible, using powerful hybrid systems that pair screw vacuum pumps for the initial evacuation with turbomolecular pumps for precise pressure control. This combination allows them to reach and maintain the ultra-low pressures required for accurate testing.

Research laboratories use similar setups to conduct advanced physics, chemistry, and materials science experiments. Basic vacuum requirements are often handled by belt-driven rotary vane pumps, which offer reliable, steady performance. High-precision turbomolecular pumps take over for more sensitive procedures, ensuring the environment meets strict experimental parameters.

Pump control systems are critical in both fields, keeping pressure levels stable from start to finish. This stability helps prevent costly errors and ensures that results remain accurate and reproducible, whether testing spacecraft components or exploring new scientific theories.

Automotive and Metallurgy

Vacuum pumps support a wide range of applications in automotive manufacturing. Pumps are integral to brake boosters, climate control systems, and emissions testing, helping vehicles meet performance and safety standards. For component testing, dry piston pumps are often preferred since they operate without oil yet still provide strong and consistent suction.

The metallurgy sector also relies on vacuum systems to enhance product quality. In vacuum furnaces, pumps prevent oxidation during metal heating and forming, ensuring cleaner surfaces and stronger materials. Precision processes, such as removing plastic parts from molds, benefit from vacuum control, which reduces defects and improves consistency.

Factories frequently incorporate vacuum conveying systems to handle materials without using mechanical conveyors. This method speeds up production while lowering the risk of contamination, making it a valuable solution for parts handling and powder transport in industrial settings.e materials to be deposited with uniform precision. Pump control systems add another layer of stability, adjusting performance to prevent sudden pressure changes that could damage wafers. These combined vacuum technologies make it possible to achieve the exacting standards required for modern electronics.

Key Considerations When Choosing a Vacuum Pump

Choosing the right vacuum pump for industrial operations involves picking a model from a catalog. The ideal choice depends on several factors that affect performance, reliability, and long-term operating costs. Understanding these considerations helps ensure your vacuum system delivers consistent results in its intended application.

Here are the key considerations:

Pumping Speed and Efficiency

Pumping speed determines how quickly a vacuum can be created and maintained. Large-scale operations like vacuum conveying systems for bulk powders may require screw vacuum pumps or belt-driven rotary vane models for steady and rapid evacuation.

For laboratory work or small-scale processes, diaphragm vacuum pumps or water vacuum pumps may be sufficient. Efficiency also matters. Choosing a pump that meets your needs without excessive energy consumption can reduce operating costs.

Maintenance and Durability

Maintenance requirements can differ widely among pump types. Dry pistons and vane pumps are popular in industries where you need to avoid oil contamination and where minimal upkeep is a priority.

In environments with demanding schedules, durable designs that allow quick servicing help reduce downtime. To keep oil-sealed pumps running smoothly, use the correct vacuum fluids. Scheduled inspections of vacuum valves and seals help improve overall reliability and performance.

Chemical Compatibility

Certain applications expose pumps to aggressive chemicals or vapors. In pharmaceutical production or chemical processing, it’s essential to select pumps made of materials compatible with these substances.

For instance, diaphragm vacuum pumps often feature corrosion-resistant components, making them suitable for handling reactive gases. Proper fluid management and filtration prevent chemical damage, extending the operational life of both the pump and the overall vacuum system.

Noise and Vibration

Noise and vibration can impact both equipment stability and worker comfort. In sensitive environments like research laboratories, quiet-running pumps such as diaphragm or water vacuum pumps are preferred.

Industrial facilities may rely on screw vacuum pumps or belt-driven rotary vane pumps with vibration-damping features. Reducing mechanical vibration also helps protect nearby instrumentation, especially in precision manufacturing.

Required Vacuum Level

The first step is determining the vacuum level your process needs. Applications like semiconductor manufacturing or advanced research often require ultra-high vacuum levels, which are achievable with turbomolecular vacuum pumps.

In contrast, food packaging or material handling lines may operate efficiently with rotary vane vacuum pumps or dry vane pumps. Matching the pump to the required vacuum level prevents underperformance and extends the lifespan of connected equipment such as vacuum valves and filtration systems.

Energy Consumptions

Energy efficiency is a growing concern in modern manufacturing. Pumps with advanced pump control systems can adjust performance to match demand, reducing unnecessary power usage.

Choosing a design that balances pumping speed with energy efficiency helps lower long-term operational costs. For example, integrating variable-speed drives into rotary vane or screw vacuum pumps can deliver both strong performance and reduced energy draw.

Conclusion

Vacuum pumps may work quietly in the background, but they touch every part of your daily life. They create the sterile chambers where vaccines are made, the airless spaces where your phone’s processor takes shape, and the sealed packages that keep your coffee fresh for weeks.

The next time you take medicine or make a phone call, remember that a vacuum pump helped make it possible. Sometimes, the most powerful technology is creating the perfect empty space for everything else to work.